半導體封裝測試設備

產品介紹

愛發所代理韓國D.I公司,其多年來致力於開發設計Burn-In測試設備,Burn-In Board及相關產品, 其作用在於提供不同環境溫度及測試條件下可提早發現測試產品的不良,以利進行後續的處理。

Package Burn-In & Tester

Test Burn-In Tester

Test Burn-In Tester系列設備設計可提供客戶最佳的Memory Burn-In 程序解決方案,不僅有良善的軟體和硬體設計,而且還有進一步升級功能,多元化的選擇將可滿足封裝完之記憶體IC廣泛的Burn-In測試要求,這樣多種類的型態可適合各種目的,例如量產,品質檢驗和研究發展,將可為您提供最佳的Burn-In測試。

Specifications

- ~ 60個slots,60 BIB,4 Rack.

- 一個zone(Temp./Control) ~ 多個zone.

- 溫度範圍: -55℃/QRA,-10℃/AF8862 ~ 150℃

- 溫度Resolution: 0.1℃

- 可測DRAM,SRAM,MaskROM,Flash,MCP..etc.

Model

- AF8852D6-For DRAM + MaskROM

- AF8862C7-For DRAM + Flash

- QRA SYSTEM-DM8827 / DM8857

Logic Burn-In Tester

Logic Burn-In Tester系列設備設計可提供客戶最佳的Logic Burn-In 程序解決方案,其良善的軟體和硬體設計,可提供多元化的選擇將可滿足封裝完之邏輯IC廣泛的Burn-In測試要求,這樣多種類的型態可適合各種目的,例如量產,品質檢驗和研究發展,將可為您提供最佳的 Burn-In 測試。

Specifications

- ~ 32/48個slots,32/48 BIB,4 Rack .

- Pattern zone : 4 ~ 32 (Option).

- ITC, ALPG Function

- Channel : 128 / 256 (Option).

- 溫度範圍:-40℃/-10℃ ~ +150℃.

- Vector Memory: 2M words(up to 4M).

Model

- DL600 series

- DL700

- DL800

- DL1100

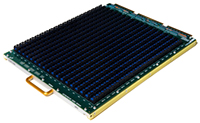

Burn-In Board

BIB (Burn-In Board)其作為半導體IC產品載具,將欲測試之IC透過SOCKET或是其他方式與BIB連結,放入測試機台內進行不同溫度,電壓,信號等等之條件反覆測試。

DRAM Burn-In Board

Specifications

- Memory IC ( DRAM , SRAM , Flash ,MCP etc… ) .

- Size of BIB : (290*630)+1mm / (450*570)+1mm .

- BIB材質:FR-4hi-ta,FR-5 or Polyamide .

- Thickness : 1.6mm .

- Pattern Layer : Multi(6Layers/8Layers) .

DLogic Burn-In Board

Specifications

- Logic IC ( MCP , SOP , STACK IC etc… ) .

- Size of BIB : (290*630)+1mm / (450*570)+1mm .

- BIB材質:FR-4hi-ta,FR-5 or Polyamide .

- Pattern Layer : Multi(6Layers/8Layers/10/12Layers) .

Fully Auto UV Tape Curing System

Features

- High intensity flash UV

- No Nitrogen gas required

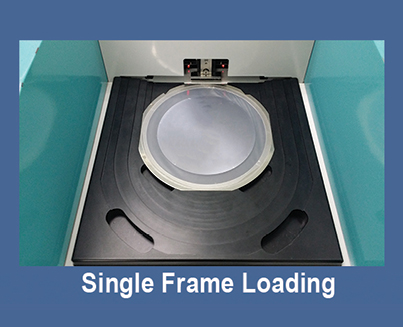

- Single frame or cassette loading

- High throughput

- High quality and performance

- Choice of UV Irradiation : 8” and 12” Wafer / Frame Curing

A2112 Fully Auto Specifications

Specifications

- High speed Flash UV Irradiation curing on UV tape (5 -10 Sec Curing time)

- No Nitrogen gas required

- No cleaning gas filter required

- Longer life span (Upto 80,000 wafer cure per lamp)

- No partial cure (100 % UV glue cure)

- Tape remains stretchable after curing

- Capable of UV irradiation for 8/12 inch wafer

- Capable of UV iiradiation for 8/12 inch wafer ring frame

Utility Requirement

- Power Supply : 220 -240 Vac,Single Phase

- Ampere: 15 amp

- Air Supply : 70 to 80 PSI

- Machine Weight : 500kg Est

- Dimension : 1070 (L) x 1080 (W) x 1150 (H) mm

相關連結